Mastering the DMAIC Methodology: A Key to Successful Lean Six Sigma Implementation

Introduction:

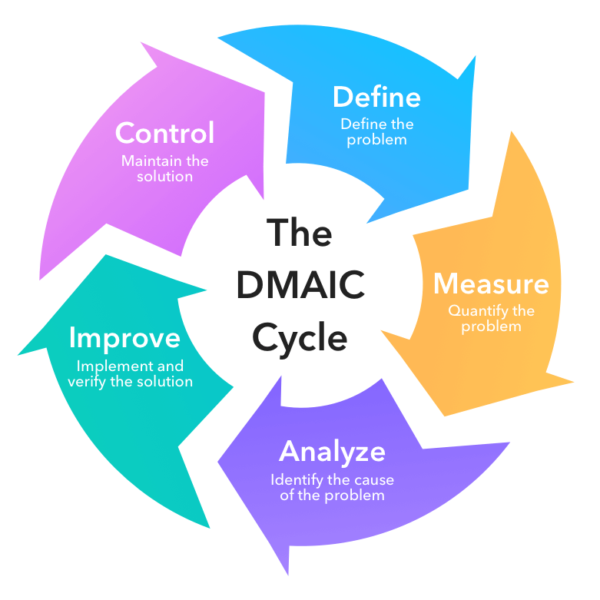

Organizations rely on Lean Six Sigma Training for its proven framework to remove waste and reduce variability. DMAIC methodology training guides teams through the Define, Measure, Analyze, Improve, and Control stages to achieve operational success.

What is DMAIC?

Organizations apply DMAIC as their primary data-based cycle to advance process and system performance. The sequence of steps in DMAIC consists of the following sections:

- Define

The Define section starts the DMAIC methodology training by outlining which issues need improvement. During this phase, team members identify project boundaries and customer requirements before setting official objectives. The project team focuses on creating a problem statement, setting goals, and identifying required resources. A detailed project charter serves as the guiding document for the entire initiative.

- Measure

Process measurement is the subsequent vital step after the current performance assessment. Establishing an exact data collection process remains critical at this assessment stage. The team must determine essential performance measurement indicators before establishing starting points for the baseline process to reveal which gaps require addressing. Process mapping and data collection plans with statistical analysis tools are common approaches for obtaining informative data.

- Analyze

The team uses analysis to study gathered information to understand what triggers process performance problems. At this point, teams use their analytical skills to identify the reasons behind defects and process variations. Combining Pareto charts and fishbone diagrams or hypothesis testing enables teams to identify main problems and prioritize solutions for solution creation.

- Improve

During the Improve phase, teams develop solutions to address the essential problems discovered during the Analyze phase. The team generates innovative process changes during this phase, which results in higher performance levels. The implemented solutions require assessment and optimization before they reach the mass implementation stage.

- Control

The last maintenance stage ensures that all improvements developed continue providing value. During this phase, the team creates control systems to detect early issues while maintaining consistent process performance. Standard operating procedures (SOPs), together with control charts and training programs, work to preserve the enhancements achieved by the organization. The process documentation during this phase ensures standardization for all organizational departments.

DMAIC constitutes an essential ingredient for organizations that aim to achieve Lean Six Sigma successes

Organizations must master the DMAIC framework to execute successful Lean Six Sigma implementation. It delivers an organized DMAIC methodology training for problem resolution. A systematic data-driven approach enables organizations to find the original causes of inefficiencies and remove them permanently without dealing with symptoms alone. DMAIC establishes a permanent improvement culture because teams regularly examine their processes to achieve superior quality outcomes with minimal costs.

Conclusion

Every Lean Six Sigma initiative requires DMAIC as its fundamental structure. Organizations follow a systematic improvement procedure through DMAIC to accomplish documented results after executing all steps properly. By successfully implementing the DMAIC methodology, organizations can improve their quality standards and minimize waste while attaining operational excellence. DMAIC is an essential business tool because its appropriate implementation fixes current problems while establishing maintenance methods for future improvement and long-term business achievement.

FAQs

- The DMAIC methodology from Lean Six Sigma is a stepwise method that includes the stages of Define, Measure, Analyze, Improve, and Control.

DMAIC is an operational framework comprising five strategic elements: define Measure, Analyze, Improve, and Control. It functions as an organized performance assessment that uses data measurements to detect process flaws and develop superior quality standards and operational effectiveness.

- The DMAIC Define phase functions how?

During the Define stage, professionals define project objectives, determine project scope, and record customer requirements. The project determines its issue while selecting essential stakeholders to achieve mutual goal alignment.

- Measuring specific stages proves essential why this methodology exists in the first place.

During the Measure phase, analysts collect data, which enables an understanding of existing process performance levels. The development of precise measurements enables organizations to discover improvement potential and set measurements that can guide performance comparison.

- The Analyze phase guides the analysis activities.

In the Analyze phase, personnel examine obtained data to discover critical causes that explain defects and operational inefficiencies: statistical instruments and analytical methods study process fluctuations and their performance effects.

- Through what mechanism does DMAIC maintain significant process transformation?

The Control phase delivers long-term solutions while creating monitoring systems to maintain the project improvements. Standard operating procedures and control plans sustain the project’s achievements throughout operations.